Gateways and access

Gratings, floors, steps, walkways, platforms, paths, guardrails, ladders, landings…

Gateways and access

Traffic structures

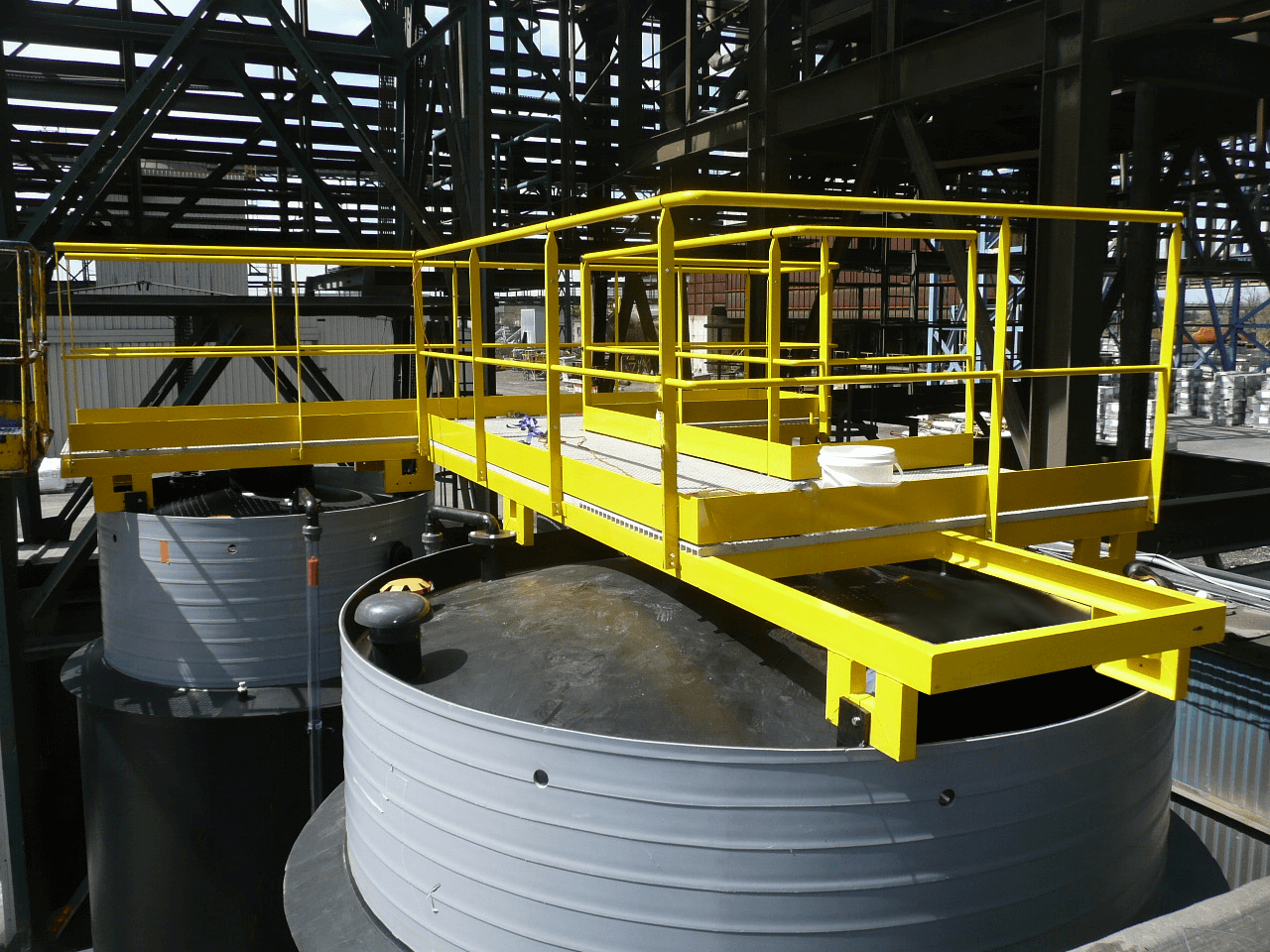

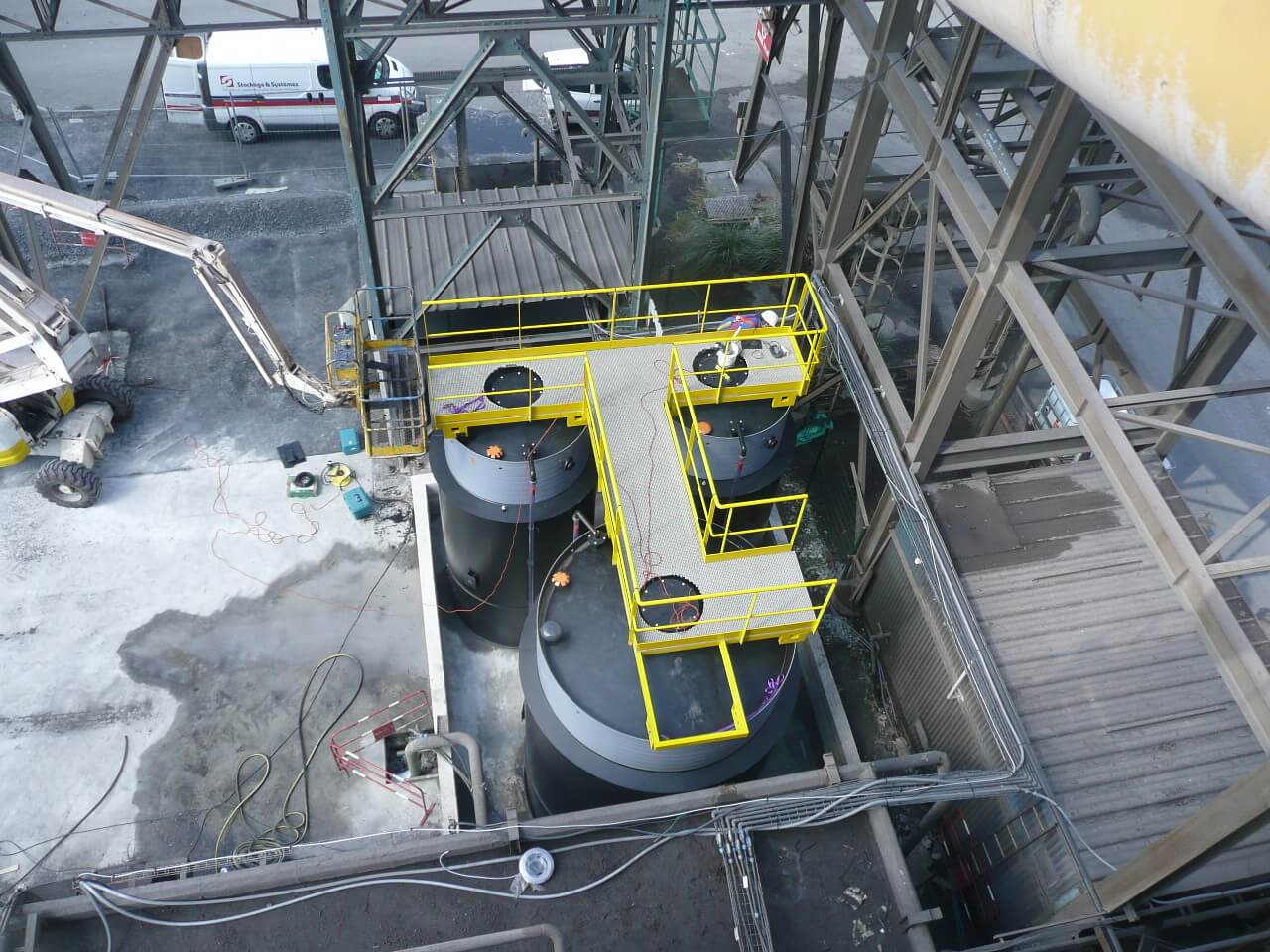

Vessels are containers widely used in industry to store liquids, gases or other substances. They can be made of metal, plastic or concrete, depending on their use. To allow people to access these tanks in complete safety, it is necessary to set up walkways and adapted accesses.

Les passerelles pour cuves sont des structures qui permettent de traverser les cuves en toute sécurité. Elles peuvent être fixes ou mobiles, et sont généralement constituées de plaques métalliques ou de matériaux composites. Walkways can be equipped with guardrails, ramps and lighting systems to facilitate the crossing of the tank. Tank accesses are devices that allow access to the interior of the tank.

In short, gangways and accesses for tanks are important equipment to allow people to work safely with these containers. They are also necessary to ensure the sustainability of industrial facilities, avoiding any damage caused by misuse of tanks.

Gateways and access

Against all aggressions

- Polyester material totally inert, insensitive to chemical products, atmospheric and saline aggressions, acid and base projections.

- No maintenance is not necessary because the color is tinted in the mass and has an anti-UV protection.

- Polyester thermosetting, as opposed to steel, is not coveted in terms of theft from mining sites.

- In order to guarantee the safety of the operators, supply of polyester grating profiles in accordance with the standards in force. On-site mounting optional.

- Mechanical strength and electrical insulation ensure safety

Our Spirit

The longevity, light weight, ease of installation and lack of maintenance increase profitability.

EELIX

Ladders and walkways

Ladders and catwalks allow access to certain points of the tank (e.g. the dome or the concrete containment) in complete safety for the operator. They are either fixed to the tank or to the environment.

Passerelles

The walkways are built with polyester resin and fiberglass profiles, which have great advantages over metal railings.

- High resistance to chemical and atmospheric agents

- Very good mechanical strength to weight ratio

- Increased longevity

- Lightness

- Constant dimensions

- High dielectric properties

- Lack of maintenance

- Easy to install

Polyester resin and fiberglass profiles offer many advantages for walkway construction. First of all, they are very strong and durable, which makes them perfect for outdoor use. They also offer better weather and UV resistance, making them more durable over time. In addition, they do not rust and do not require regular maintenance. They are also lightweight and easy to handle, which makes them ideal for installations where the load bearing capacity is limited. In addition, they do not rust, twist or warp, making them very reliable and safe to use.

The walkways are designed and built according to the standard

NF EN 14122 2-3.

Structures

The supporting structure is built with type C and/or type I profiles, fixed together with transverse profiles of the same type and chosen according to the required loads. The load-bearing structure of a polyester resin and fiberglass walkway can be constructed with different types of profiles depending on the loads it must support.

Type C and Type I profiles are often used for their high strength and ability to resist bending and torsion forces. These sections can be fastened together with cross-sections of the same type to strengthen the structure and improve its stability.

In some cases, additional reinforcements can be added to increase the structure’s resistance to heavier loads.

At the very end of the walkway, the minimum load in use is considered to be 20 dN/m2 (uniformly distributed load) as required by the standard.

Connections are made with stainless steel plates and bolts.

Floors

The floor is made of polyester grating which is chosen according to the required loads, finally the minimum load of use must be considered of 1,5 kN (concentrated load) as required by the norm.

Guardrails

The railings are made of profiles assembled with rivets.

The distance between the posts is about 1.2m (maximum 1.5m). The posts will be fixed to the structure with stainless steel bolts. The guardrails of a gangway in polyester resin and fiberglass are generally made of polyester resin and fiberglass profiles assembled with rivets.

This assembly technique creates strong, durable railings, while providing flexibility in designing different models and styles. Profiles can be chosen to fit any size and shape, and can be easily cut and assembled on site to fit the needs of each project.

Polyester resin and fiberglass railings can also be painted or lacquered in a wide variety of colors to blend harmoniously with the environment.

Échelles

The ladders can be installed in conditions of chemical aggression and intense corrosion.

They are made of polyester resin and fiberglass profiles, the rungs fixed with FRP dowels.

According to the standard the distance between the rungs must be 300 mm. The fastening is done by stainless steel or polyester clamps and must be put every 2000 mm approximately (at least two pairs for each ladder).

- Poteau

Profilé rectangulaire fabriqué avec la technologie Pultrusion utilisant résine polyester isophtalique et renforcé avec fibres de verre.

Section rectangulaire 85x25mmépaisseur mm 3. - Échelon

Profil circulaire type “O2821.3” fabriqué avec la technologie Pultrusion utilisant résine polyester isophtalique et renforcé avec fibres de verre. L’échelon a une surface plissée pour le rendre antidérapant.

Section circulaire Ø 28×21,3mm épaisseur 3mm.

Caillebotis

Gratings are primarily used in industrial environments to protect the floor and ensure worker safety. They are often used in areas where chemicals and corrosive products are stored, handled and transported, as they allow for the drainage of possible leaks and spills of these products.

Gratings are also used in garages, workshops, warehouses and production halls, as they allow for easy water and dust drainage, while providing a non-slip and safe surface for workers.

There are several types of gratings, differing in material of construction, shape and size. It is important to choose the type of grating that best suits your work environment and your safety and durability needs.