High strength extruded-wrapped tanks

High-strength tanks designed for complex applications, highly corrosive products and large volumes

Extruded-coiled tanks: sensitive storage

Priority to safety

Our vertical tanks are manufactured by extrusion-rolling according to the SCHOELLER-ALLIBERT technology taken over in 2016 and meet the storage requirements of many trades in the chemical and parachemical, pharmaceutical, water treatment and nuclear industries.

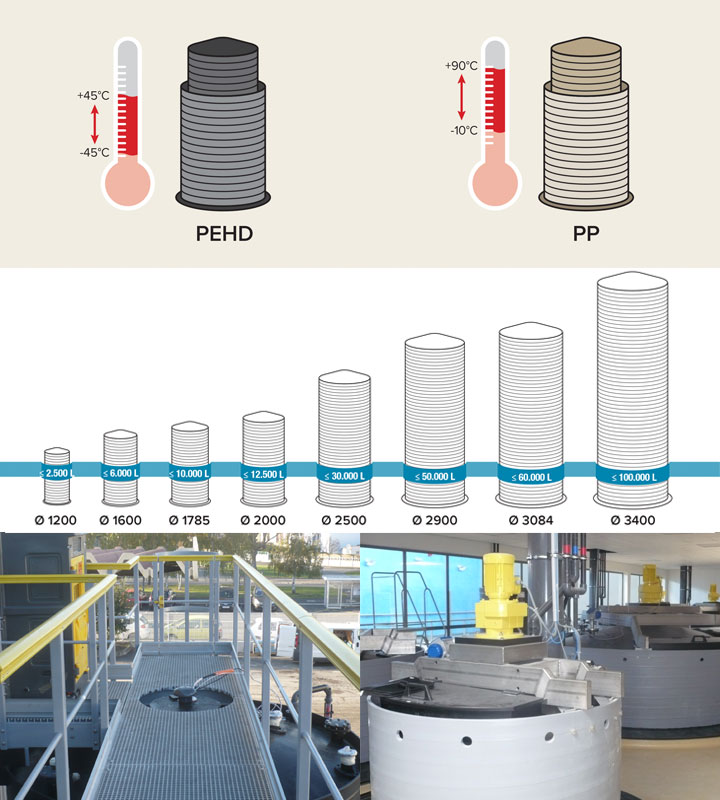

They are intended for the storage of dangerous products, concentrated acids and bases, acid and basic effluents, in temperature ranges from -45°C to +90°C.

Extruded-coiled tanks

The sectors concerned

Chemicals, petrochemicals, pharmaceuticals, cosmetics, perfumery, shipbuilding, food processing, water treatment, air treatment, cement industry, metallurgy, nuclear power, surface treatment, chemical distribution, laundry, dyeing, paper industry, etc.

The 20 most stored products in EELIX tanks

|

|

Extruded-coiled tanks

Technical performance and chemical accounting

- Chemical resistance : The chemical inertia of HDPE (high density polyethylene) and PP (polypropylene) guarantees reliable storage for corrosive and dangerous chemicals, bases or acids. The exceptional chemical inertia of our materials offers a great versatility in the use of our tanks, whether for the storage of concentrated acids, strong bases, effluents of all kinds, or other dangerous products.

- Our specially selected materials are UV-resistant and resistant to the most extreme weather conditions (-45°C to +90°C). Our tanks can therefore be installed indoors or outdoors. They can be calculated according to the Snow and Wind standards of each region.

- Mechanical resistance: the EXTRUSION ENROULEMENT MASSIF EELIX (ex SCHOELLER-ALLIBERT technology) allows to optimize the resistance of HDPE and PP. Our ferrules are calculated according to the DVS 2205 and EN 12573 standards and manufactured by EXTRUSION ENROULEMENT MASSIF. The material is wrapped around a mandrel at its melting temperature. The thickness is perfectly controlled and the material thus transformed makes it possible to obtain a 100% homogeneous ferrule without welding, which can reach 120 mm in thickness.

- The ferrule is a homogeneous bloc, free of internal stress and with the best chemical resistance that HDPE and PP can offer.

- Tank with integrated retention (also called double envelope, double wall or double skin)

- Increased safety thanks to the double envelope: by its presence, the external retention tank (or double envelope) guarantees a compliance of the storage in cases where there is no other system of recovery of the possible risks of spillage.

- Adaptability of the tanks: each tank can have a different function (long term or short term storage, mixing, dilution of powders, special manufacturing, neutralization of liquids, etc.). Thanks to specific equipment such as: access on domes and walkways, gas scrubbers, heaters, mixers, cooling units, unloading boxes, pumping boxes… EELIX tanks and retaining tanks are available to create a complete storage environment.

- Traceability guaranteed for the materials used.

- Important thermal insulation.

- Recyclability of the material: EELIX tanks are 100% recyclable, even after 30 or 40 years of use. Our materials fit perfectly into a circular economy mode.

Extruded-coiled tanks

Configure your tank

Choice of material

En fonction du produit stocké et de la température de stockage.

PEHD (-45° à +45°C – de couleur noire)

PP (-10° à +90°C – de couleur beige).

Choice of the series

The tanks comply with the EN 12573-2 standard based on the nature of the stored product in terms of concentration, density and corrosion factor (A2K).

- Série CHIMIQUE : density ≤ 1.4

- Série LOURDE : density ≥ 1.4

- Série OXYDANT : sodium hypochlorite and hydrogen peroxide

- Série SPÉCIALE : concentrated sulfuric acid or nitric acid

Retention

With retention for increased security or without retention.

Choice of the size

- De 2000 L à 100.000 L

- 8 diamètres intérieurs allant de Ø 1200 mm à 3400 mm

- Les hauteurs cylindriques sont données à titre indicatif, toute hauteur intermédiaire est réalisable sur simple demande.

- Voir le tableau des dimensions.

Choice of accessories

- Main accessories

- Access and gateways

- Gas scrubbers

- Warmers

- Agitateurs

- Accessoires secondaires : trous d’homme, piquages, tubes de remplissage, ceintures et sangles, bondes de sécurité, collerette anti-pluie, vannes, mesures de niveau, pattes de fixation.